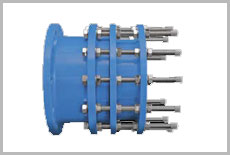

Dismantling Joints

We are offering the most impeccable range of Dismantling Expansion Joints which are used in the pipelines where valves are sometimes withdrawn for the future maintenance or replacement. These joints are essential parts for the designing of the pipelines and valves. Some of the key features of the Dismantling Expansion Joints are:

- Aids effectively during the installation and un – installation of the of the pipe sections and valves

- Offers longitudinal adjustment to the piping system

- Help in correct fitting of the valve

- The joint can be installed to the exact length which is essential for connecting the flanges securely

- For the reverse sequence, the readjustment of the dismantling joints brings enough space to withdraw the valve

- Increase efficiency

- Reduce site operations and downtime

- Find wide usage to fill gaps where a pump in installed in a particular position and is connected to a pipe protruding from a wall

The Design Principle

There are numerous versions of the Dismantling Joints available in the market, but the basic principle of these joints remain the same. The principle is as follows:

- The flange adapter, located on one side of the dismantling joint, is connected securely to the pipe or valve with the help of the flange. Flange bore holes as according to the respective pressure rating or standard are available.

- The flanged spigot comes with a flange at the other end of the dismantling joint which is required for connection in the other direction and is pushed into the flange adapter.

- For the installation and removal of valves with longitudinal adjustment of maximum ± 50 mm, these two parts can be forced against one another in order to insert the dismantling joints between the pipe sections or pipeline and valve.

- The gasket is compressed with the tightening of the nuts between the end-ring and the central ring. These are pushed against the pipe of the flanged spigot. The rubber gasket is of premium quality that ensures that the system is always leak proof.

Threaded tie-rods are mainly used for the following restraining and flange connection, depending on the kind of dismantling joint used. Simultaneously, they also work to transfer the forces occurring from one side of the dismantling joint to the other side.

Technical data

Size Range: DN 100 – DN 2400

Customer Benefits

- The simple operations of the fittings make them effective for many applications including water treatment, pumping stations, plant rooms, sewage treatment plant, meter chambers, power generation station, gas distribution stations.

- These Dismantling Joints offers simple and easy installation and removal of isolation valves, control valves, non-return valves, check valves, pump sets, flow metering valves, pressure reducing valves, flanged type pipe & fittings.